Back in the day…

When I was a kid (back in the 80’s), I used to come home from school and watch

a great TV show about future technologies. I don’t remember the name of the

show, but it had some interesting ideas. One of those ideas was this notion of

having your own miniature manufacturing machine in your home that could make

anything with plastic. I had seen my first 3D printer, and I’ve wanted one

since then.

The printer

Geeetech i3

Geeetech i3

Pro B MK8 (Prusa Clone)

A few weeks ago, I received my first 3D printer in the mail. I ordered the

Geeetech i3 Pro B clear acrylic model from

eBay.

I decided to go with this printer based off of a few comments that were made

in this YouTube video from “Design. Prototype. Test.”:

Assembly

When it arrived, I got started putting it together. There was no assembly

instruction manual included with the printer, but there was a very thorough

parts list and a link to a PDF containing the assembly instructions. Within

the PDF, there were links to YouTube videos for many of the assembly steps, so

assembly was easy (to me).

This kit isn’t for the beginner. It requires a lot of thinking and problem

solving. If you want a printer that you can just take out of the box and start

printing after a few minor adjustments, you’ll want to spend a bit more money

and go with a Creality CR-10 or other such commercial printer. This kit was

less than $200, but you’ll spend the difference in the time it takes to get it

up and running effectively. It’s a trade off between time and money. I really

enjoy tricky and puzzling endeavors, so this was the perfect kit for me.

It took me about 5-6 hours to put it together as I went slowly to make sure I

didn’t overlook anything. There’s a lot of information about this printer on

the web, but you have to search Google and Facebook to find it. Once located,

there are many people who can help you with your assembly if you should run

into any problems. I ran into a few beginner issues that I quickly solved by

simply searching for the solution on YouTube or Google.

There were some mechanical issues that I ran into. One interesting problem

required the use of fire. One of the drive belt pulley housings was too tight

for the wheel to move freely, so I had to apply outward pressure on one side

while applying heat to the joint. When it cooled, the pulley would move freely

between the two edges. Here’s a picture of how I had to hold it with a pair of

pliers while applying the heat:

Engineering

Engineering

at its finest

Assembling the printer was very rewarding. It was really neat to see it come

together as I progressed through the steps.

The printer

The printer

base with bed

Fan

Fan

assembly

Post-build learning

After I had the printer built, I started down the path of actually learning

how to use it. I had already watched quite a few videos about 3D printing, but

I wasn’t sure exactly how to get started.

One of the resources I used was the Geeetech i3

Wiki.

Here’s the basic workflow that I discovered:

- Find a 3D model to print – I decided to use a 20mm calibration cube as my first print because it was big enough to have some substance, but small enough to manage.

- Download the software – You’ll need at least two pieces of software in order to print your model: a Slicer and a printer host (unless you’re using the SD card approach – which I’m not). I downloaded the Repetier Host from Geeetech that is made specifically for this printer. This includes the other piece of software that you’ll need: a Slicer. However, I never could get the included slicer (Slic3r) to work, so I ended up downloading the latest version of Ultimaker Cura. Cura worked right away for me after an hour or so of failed prints using Slic3r.

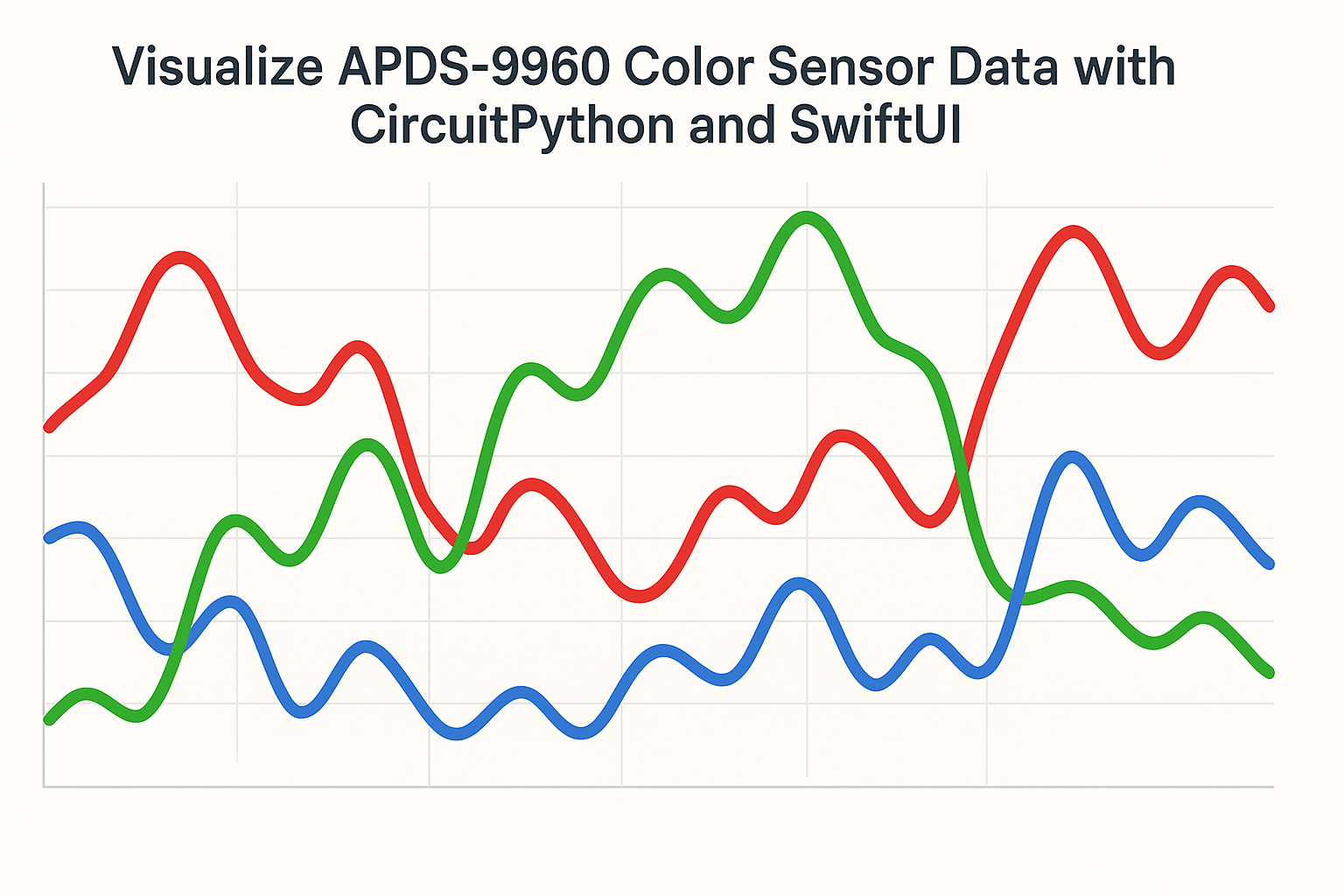

The slicer software will convert the 3D model into G-Code, which is the code

used by the printer to know the x, y, z, and extruder coordinates to use when

printing an object. There are a lot of settings to work with to get your

prints working. Each printer is different and each printer/filament

combination will require adjustments to temperatures.

My filament was Inland 1.75mm black

filament

at $20.99 for a kilogram. It has a recommended temperature range of 205°-225°

Celsius. I’ve found that running it at 216° is what works best for my printer.

I keep my print bed heated to 60° (all future temperatures will be expressed

as Celsius).

Results

Here is the evolution of my first four prints.

Top left: My first attempt at using Slic3r. As you can see, I had no luck with

this. I didn’t really know what I was doing and the Slic3r is not inuitive.

I got a little better and had better results with the top right “cube”.

Bottom left: This was my first print using the Cura slicer. Still not good,

but at least I got a whole cube this time.

Bottom right: my second print with Cura (and fourth overall print). I had

better layer adhesion because I adjusted my extruder temp from 200° to 210° (I

had not yet experimented with the temperatures to find the target temp for

this filament). I got a good cube, but the top of it was rough because I was

not using a part cooling fan.

Expanding the printer

That leads me to the next topic: Expansion. I bought this printer because it

is a great candidate for upgrading. It’s easy to print replacement parts and

parts to improve the print performance of the printer. The first part I wanted

to print was a part cooling fan. This allows you to print longer bridges

(where the printer prints into “thin air” between two edges). It makes much

nicer edges, as well.

First fan

First fan

housing

After many failed attempts at a perfect part cooling fan housing, I was able

to find the perfect one by contributing to the “Design, Prototype, Test”

Patreon campaign. As a

contributor, he gives you access to designs that he’s personally created for

various 3D printers that he owns. He’s created a few parts for the Geeetech i3

Pro B as well as a custom firmware upgrade that adds support for a sensor that

allows for auto bed leveling.

Part cooling

Part cooling

makes a difference. The cube on the left was printed with the part cooling fan

attached. The one on the right had no part cooling. As you can see, the

bridges of the top did not print correctly and the plastic dropped down into

the cube on the right.

Here’s a fan cover that I printed:

Bed leveling

The print bed must be perfectly level before starting to print. That’s the

main issue I’ve had so far. By level, I don’t mean putting a level on the bed

and adjusting it. It must be level relative to the X and Y axes. Bed leveling

is an involved process and it’s hard to get it right. It’s probably my least

favorite task, but every printer owner has to do it.

Bed adhesion

Once the bed is level and the temperature is correct, the next thing to manage

is bed adhesion. This is the ability of your print to stay attached to the bed

while printing. The first layer is the most critical layer. I’ve had most of

my prints fail on the first layer. Many people use different surfaces to print

on, but I’ve had good luck just printing onto the glass surface of my printer

without the need for glue stick or hair spray. I have had to use a brim (a

single layer of plastic about 8mm wide that attaches to the item much like the

brim of a hat).

Z-Axis Banding

Perhaps the biggest problem after first layer adhesion has been z-axis

banding. That’s when there are visible bands along the z axis on the print. I

printed some specialized adapters that modify the printer to eliminate most of

the banding issues, but I still have a major issue where my prints are showing

major weakness at about 50mm high. It is visible below the white film on the

head of the Darth Buddha figure shown here (the white film is glue residue

from where I had to glue the head back on):

Justification

One of the main reasons I wanted to get a 3D printer was to print enclosures

for my electronics projects. I was able to find a great enclosure for my Mojo

FPGA. It printed out in two parts and used standard M3 screws and nuts.

I was still having temperature issues with my extruder when I printed this, so

the first few layers didn’t extrude properly, giving me some imperfections in

the top layers. However, I am pretty happy with how this turned out overall.

The Mojo now

The Mojo now

has a home

Custom Items

Another exciting aspect of 3D printing is the idea that I can make my own

items. I needed a coat hook for my cubicle at work, so I measured out the

space. I came home and accessed Tinkercad to create

my first item for 3D printing. Version one of my coat hook was too big and a

bit on the ugly side. So, I remeasured using digital calipers. Version 2 was

much nicer looking and fits the space perfectly. It even holds my coat!

Coat Hook v1 (ugggly)

Coat Hook v2 – Perfect!

Conclusion

This has been an exciting journey for me. I’ve really enjoyed learning about

3D printing and assembling my own printer from just a big pile of parts. It’s

very satisfying to see it spitting out usable objects. While frustrating at

times, the hobby has been an overall joy. I highly recommend 3D printing to

anyone with a creative spirit that doesn’t mind a little bit of a challenge.

The rewards are there.

I leave you with “Darth Buddha”

An hour of live 3D printing of part of the Darth Buddha figure